For those concerned with climate change, nuclear energy presents a distinct advantage: It’s free of carbon and other greenhouse gases.

But splitting atoms to run homes and factories still gives pause. For one, there’s the long-lived radioactive waste reactors generally produce. Then there are safety concerns, highlighted by 2011’s Fukushima Daiichi disaster, when an earthquake and tidal wave damaged a nuclear power plant and spread radiation.

More efficient reactor designs could mitigate these problems. Argonne National Laboratory researchers are applying the power of high-performance computing (HPC), combined with sophisticated experiments, to refine plans for one, the sodium-cooled fast reactor (SFR).

The SFR uses uranium more efficiently and could even outlast the century-long lifespans of today’s water-cooled nuclear reactors, but they have a big problem: If the sodium metal coolant interacts with air or water, it can burn or even explode. That makes it expensive and difficult to test SFRs’ performance and safety.

Computational models and simulations can help fill the gap, providing critical tools to understand how sodium metal coolant behaves in SFR fuel cores, especially how it flows around the complicated geometry of wire-wrapped fuel pins, says Elia Merzari of Argonne National Laboratory.

Merzari and other Argonne scientists, collaborating with industry partners TerraPower of Bellevue, Washington, and AREVA of Lynchburg, Virginia, have conducted HPC simulations that can support designs for efficient and safe SFRs.

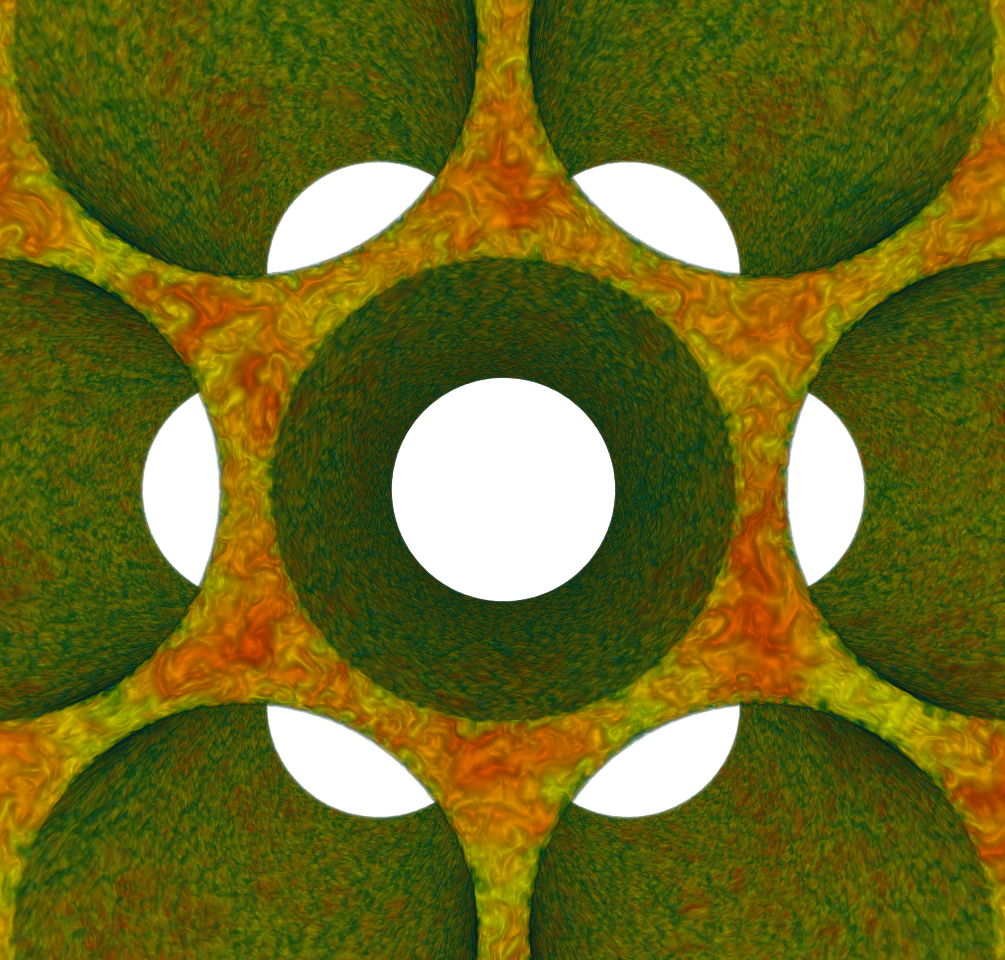

Teasing apart the details of fluid flow within SFR reactor cores is challenging. SFRs hold thousands of parallel uranium-filled pins or rods, arranged in bunches of 61 to 271. A helical spiral of wire surrounds around each pin to keep it from interacting with its neighbors. Liquid sodium coolant is pumped through the core and flows between and around these complex shapes.

Experiments provide essential benchmarks for understanding SFRs’ behavior, Merzari says, but they only fill in part of the picture. Detailed computations help researchers understand sodium’s behavior in reactor regions beyond the reach of experimental probes or where conditions are too extreme to measure experimentally.

The number of fuel pins in a reactor critically influences coolant behavior.

It’s incredibly difficult work, Argonne’s Aleksandr Obabko says. “The sodium is in a complex geometry. The wire wraps around the pins, and those structures create a lot of turbulence, a multitude of vortices on different scales.” The vast size range involved also complicates calculating fluid flow’s subtleties. The tiniest swirls around wires can be millionths of a meter in size, but their cascading effect produces physical forces on the scale of meters. And these changes occur in milliseconds.

Calculations that span this range are so demanding that modelers have had to make restrictive assumptions so HPC systems could complete them in a reasonable amount of time.

But access to the huge machines at Argonne’s Leadership Computing Facility lets Merzari and his colleagues simulate these phenomena with far fewer assumptions. “We’re the only ones in the nuclear field who are working on this scale with these sorts of complex geometries.”

The team is using an ASCR Leadership Computing Challenge award of 72 million processor hours on Mira, the lab’s IBM Blue Gene/Q, to get a sharper picture of the turbulent eddies that form as sodium metal flows around fuel assemblies. The DOE Office of Nuclear Energy also supports the work through its Advanced Reactor Technologies and Advanced Modeling and Simulation programs.

The team’s simulations found that the number of fuel pins in a reactor critically influences coolant behavior. Flow can change drastically when there are fewer than 61 pins, but above that number “things become less dependent” on pin count, Obabko says.

The findings are important for designing effective experiments. Researchers typically try to economize by designing test assemblies with a small number of pins, Merzari says, but the simulations indicate the results may not reflect how larger reactor cores work.

The team is moving from studying flow behavior alone to considering how heat and radiation affect coolant circulation. The pins give off heat and radiation as the uranium fuel in them is spent. That can cause the pins to swell and deform, changing how coolant flows around them. “What hasn’t been quantified is the impact of these deformations on the flow field and the impact on heat performance,” Merzari says. So far the researchers have focused only on the flow behavior around individual pins within a group, but heat and swelling are likely to affect a group as a whole.

The team’s close collaborations with experimentalists at Argonne, Texas A&M University and other institutions is critical to its study of 61-pin reactor assemblies. Because both approaches are proceeding concurrently, Merzari and Obabko can immediately talk with experimentalists if they don’t understand their simulation results. “Advanced modeling requires advanced experiments. It’s more difficult than in the past and requires closer collaboration,” Obabko says.

What the Argonne team learns about SFR fuel and coolant behavior could be used around the world to design safer, more efficient nuclear reactors. The team already collaborates with European partners through the International Nuclear Energy Research Initiative, sharing data from high- level simulations that helps researchers make the most of expensive, reactor-scale experiments.

With a more complete understanding of how reactor geometry, heat and radiation affect coolant flow, researchers could eventually design SFRs that can shut themselves down to avoid overheating, Merzari says. And simulations can help researchers greatly cut the cost to develop these new reactors while ensuring they operate reliably and safely.