Four years after his Ph.D., turbulence and combustion modeler Bruce Perry has drawn a plum assignment.

He and colleagues are loading software called Pele – named for the Hawaiian fire diety – into the world’s speediest supercomputer to evaluate whether new, green jet fuels could reduce global warming.

Perry and colleagues are working on Frontier, the Department of Energy Oak Ridge Leadership Computing Facility’s new exascale machine and rated the world’s most powerful computer.

They need to work there because “the simulations we do are very, very computationally expensive,” says Perry, a researcher in high-performance algorithms and complex fluids at the National Renewable Energy Laboratory (NREL) in Golden, Colorado.

Allocated 320,000 node hours that they started expending last July, “we have had excellent experiences working on Frontier,” he reports. “We were able to iron out issues and demonstrate good performance while using almost the entire machine.

“With the simulations in this project we hope to demonstrate that the Pele suite can be effectively used to predict the impact of sustainable aviation fuels properties on combustor performance.”

Pele enables researchers to simulate combustion in a variety of fuels in unprecedented detail and is a collaboration of five DOE national laboratories, the University of Connecticut and the Massachusetts Institute of Technology. Pele is a product of the Department of Energy’s Exascale Computing Project (ECP). The ECP just ended a seven-year run building tools that comprise the ecosystem for exascale computing at a billion billion operations a second.

Sustainable aviation fuels, or SAFs, are cited by NREL as capable of achieving “a minimum of 50 percent reduction in life cycle greenhouse gas emissions compared to conventional fuel.”

They could do so by replacing fossil fuel extracted from below the surface. Instead, SAFs substitute derived feedstocks from above-ground: corn grain, oil seed, algae and forestry products and even solid waste and wastewater treatment sludge.

Perry studied chemical engineering at Northwestern University before switching to mechanical and aerospace engineering at Princeton. He notes that unlike those in fossil fuels, the carbon dioxide molecules emitted by SAF’s can be discounted in greenhouse gas bookkeeping.

That’s because their carbon atoms already reside on Earth’s surface. “When SAF is burned it is just putting CO2 back into the atmosphere where it started,” he explains. “So there are no new net CO2 emissions.”

Perry first became captivated by fluid mechanics at Northwestern, “drawn to the ability to create relatively simple mathematical models that explain extraordinarily beautiful and complex phenomena that we observe in nature and our daily lives.”

On Frontier, he is among several NREL investigators for the fluid mechanics-rich Pele project, which can harness the operations of 644,096 supercomputer cores capable of calculating more than 1 quintillion operations each second. A quintillion, or a billion billion, is delineated by the number 1 followed by a string of 18 zeroes.

‘If we can run high fidelity simulations of their fuels in an aircraft combustor, we can get some confidence of how they will perform.’

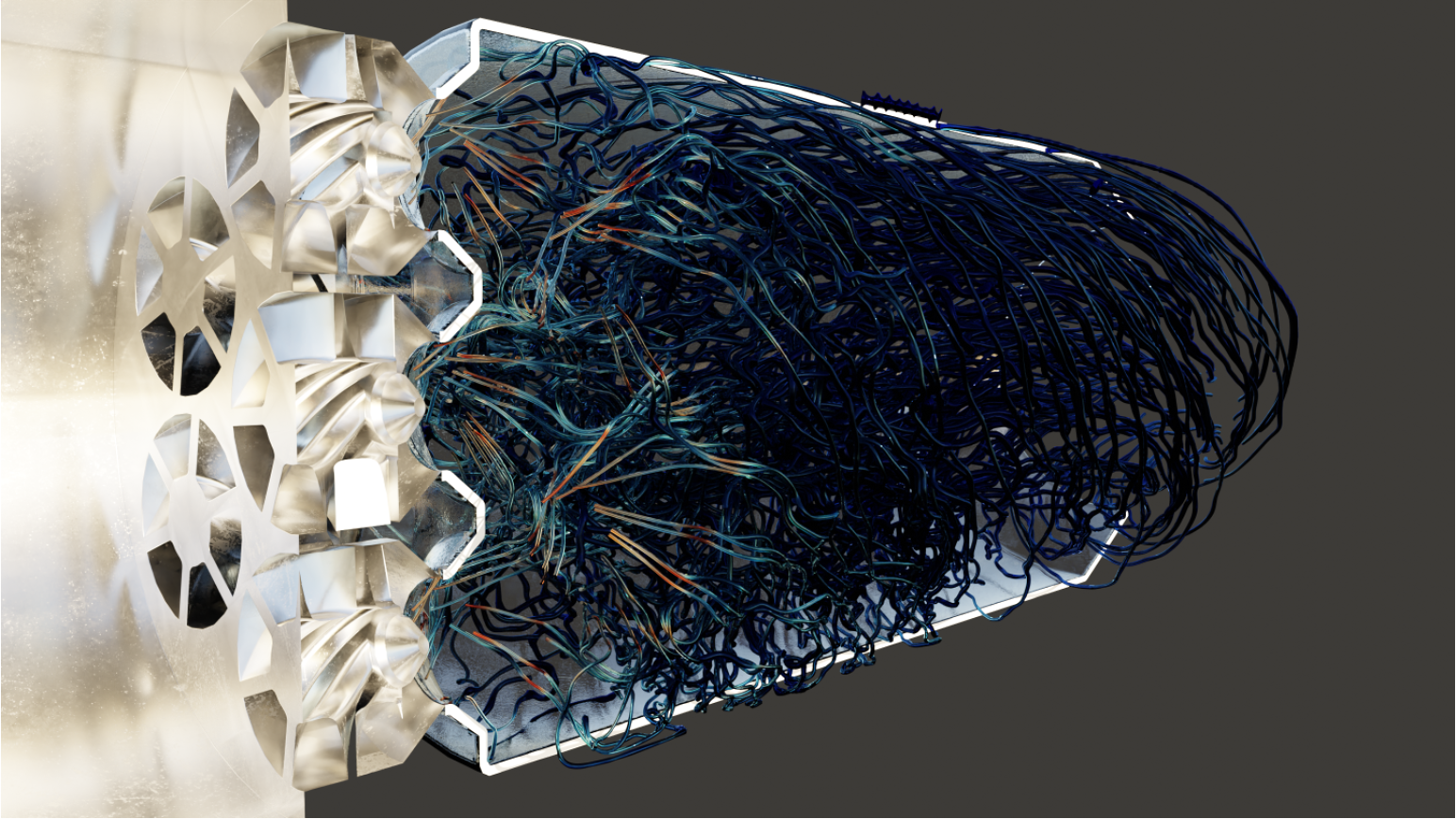

Pele software can simulate “fluid flow and chemical reactions in devices with complex geometries,” Perry says. Specifically, it “breaks up the inside of an aircraft combustor into a very large number of tiny volumes.”

Pele also “keeps track of mass, energy and chemical species flowing in and out of each volume” as well as all the chemical reactions within. All told, it can handle up to 100 billion volumes simultaneously, allowing DOE simulators to generate overwhelming arrays of color-coded graphics that experts can track.

Initial plans are to use Pele and Frontier to evaluate “two particular SAF candidates” that are among “the furthest along in terms of development and production,” Perry says.

Some proposed SAF formulas have gone through a detailed four-step certification process to be used as blends with petroleum-based jet fuel, but no pure, above-ground-source SAF has been certified for commercial use, an aviation industry goal.

What’s preventing that certification is the expense to fuel-producing companies, which must provide thousands of gallons of costly candidate fuels for testing before being approved, thus risking millions of dollars if they are not certified.

Perry says that “if we can run high fidelity simulations of their fuels in an aircraft combustor, we can get some confidence of how they will perform before having to do the actual experimental tests and having to make all that fuel.”

A collaboration that links the supercomputer, industry and academia with Perry’s own lab is working to make that happen.

NREL also has a Fuels and Combustion Group that is “obtaining small samples of SAFs to experimentally measure these properties,” Perry says. “We need to know the chemical properties, including viscosity, surface tension and heat of vaporization. Those properties of SAFs are not yet well-established.”

Meanwhile, engine manufacturer GE Aviation is developing a new combustor for supersonic commercial transport that “allows combustion to occur more uniformly” and would eliminate “hot spots and fuel-rich spots that lead to the formation of harmful pollutants like soot and oxides of nitrogen.”

GE Aviation also is collaborating with experimentalists at Georgia Tech, notably Professor Adam Steinberg, who can make difficult measurements, adds Perry.

“Professor Steinberg has one of the few labs in the world equipped to do this. It requires special pressure vessels, special combustors fitted with transparent quartz windows and complex sets of lasers.”

That gives modelers like Perry vital ground-truthing data. “We are able to take all their experimental data and use it for validation of our simulations.”

At NREL, Perry has relied on Sreejith Nadakkal Appukuttan, the researcher who runs most of the Pele simulations on Frontier, Shashank Yellapantula, who supervises all simulation-based SAF research there, and group manager Marc Day, who has been the driving force behind the Pele code.

Hundreds of national lab investigators have been involved over the past seven years in the DOE-funded Exascale Computing Project to develop software such as Pele that can run on both Frontier and Aurora, a similar sized supercomputer at Argonne National Laboratory.