Scientists constantly identify and qualify new materials, seeking substances with improved properties for use in everything from cars to space capsules.

Getting those compounds out into the world, however, is arduous, says the University of Texas at Austin’s Feliciano Giustino. “People realized that from a new material being discovered in a lab to using it in devices – everyday consumer kinds of applications – takes several decades,” he says.

The decades-long lag in materials’ acceptance arises mostly because, Giustino explains, “once something has been made in the lab, there are many issues to sort out, and there are problems with scalability in the processes and integration.”

Even devising an idea for a new advanced material stalls the process. “Finding materials is very challenging because we have a periodic table with more than 100 elements that can be used, and combinations of those are on the order of hundreds of millions of materials,” says Giustino, who holds the W. A. “Tex” Moncrief Jr. Chair in Quantum Materials Engineering at UT Austin.

To accelerate the process, the Materials Genome Initiative (MGI) was launched in 2011. The MGI’s goal: to shorten advanced materials’ path to the market at a fraction of the cost by harnessing the power of data and computational tools in concert with experiment.

Giustino focuses on improving materials that can be used in energy-related applications. For example, he and his colleagues received an ASCR Leadership Computing Challenge allocation on the Argonne Leadership Computing Facility’s petascale supercomputer, Theta, to design new semiconductors. The work also is supported by the DOE’s Basic Energy Sciences program.

‘Facilities like Argonne National Lab are essential to carry out the simulation because these calculations cannot be performed on a laptop or a desktop.’

Giustino’s atom-scale simulations incorporate quantum mechanics, the strange physics that govern matter at the tiniest scales. That’s a change from decades ago, when that approach was merely an intellectual exercise in fundamental science. Now, Giustino says, “we have equations that can be solved to predict properties of real materials with an accuracy that can match experimental data, even before experiments are realized.”

The work starts with a hypothesis for a new material that could exist or might not exist. The researchers then calculate what the proposed material would do.

First: computing the material’s stability. “If somebody makes it, will it decompose into some byproducts?” Giustino asks. If computations suggest a material would be stable, the researchers move on to other properties. If it’s a solar cell material, for example, researchers would want to know whether it efficiently absorbs light and converts it into electricity.

More specifically, Giustino determines if the material absorbs light in the solar-emission spectrum, which is mostly visible and infrared light, and how efficiently it could convert those photons into electrical currents. “All of this can be translated into very clean mathematical requirements.”

With those equations in hand, calculations can begin. “To predict these properties at the atomic scale, you have to solve equations similar to the Schrödinger equation of quantum mechanics, and for real materials that becomes very challenging,” Giustino says. “So facilities like Argonne National Lab are essential to carry out the simulation because these calculations cannot be performed on a laptop or a desktop.”

Designing and calculating a potentially beneficial material’s properties is just the start. If Giustino’s team discovers something interesting, it connects with experimental groups that take the next step: attempting to create the material in the lab.

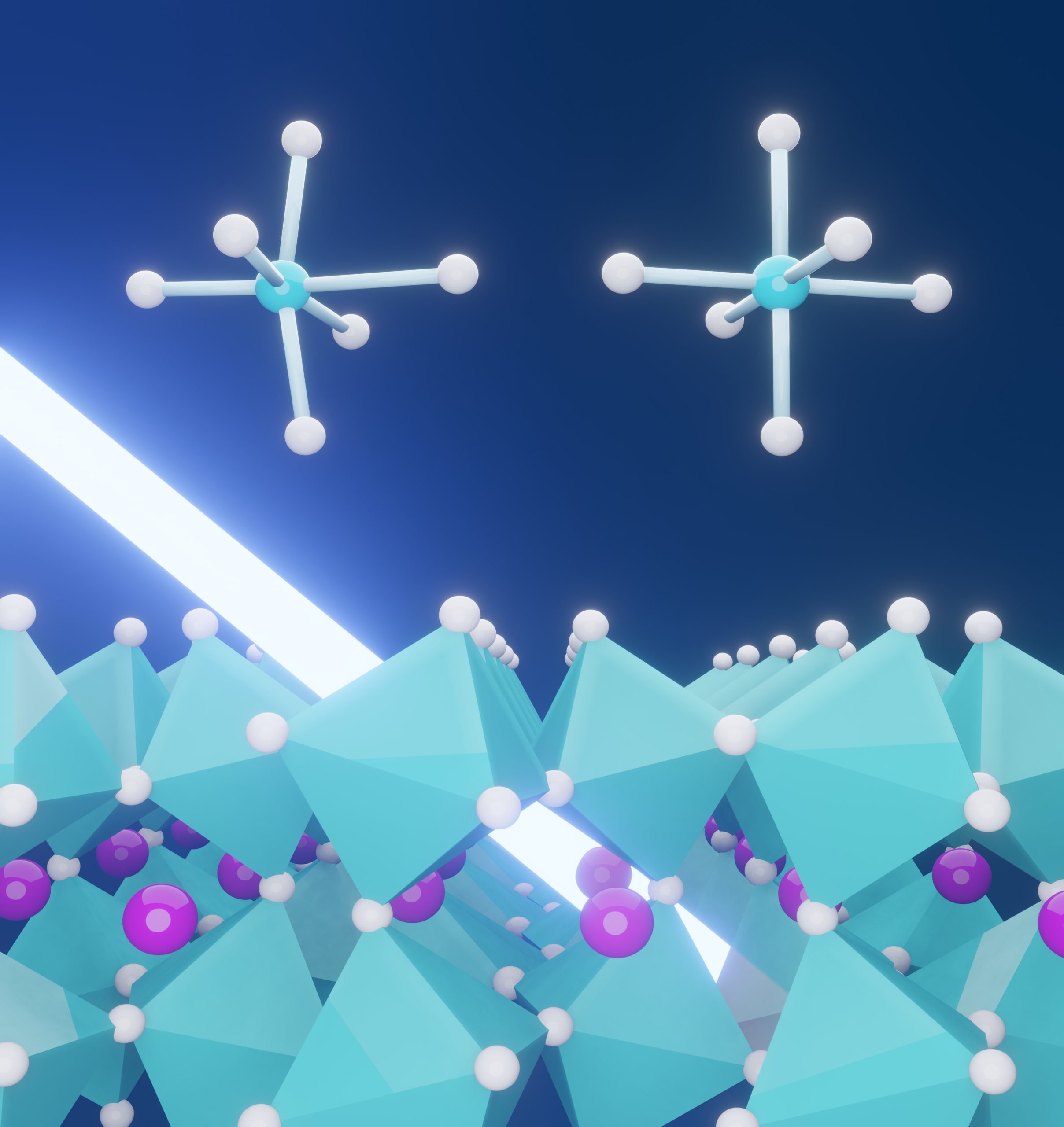

If absorbing light can make electricity, the reverse is also possible. A light-emitting diode (LED), for example, performs this trick. Giustino worked on an LED based on lead-iodide perovskites, which efficiently turn electricity into light. That material, though, suffered from a crucial problem: lead’s neurotoxicity.

Giustino’s team accepted the challenge of designing a similar lead-free material. “We basically tried to replace lead by checking every single element,” he says, “and that led to the discovery of three or four compounds that were good candidates.”

One of those, a perovskite composed of cesium, indium, silver and chlorine (Cs2InAgCl6), met the desired criteria, and Giustino and his colleagues synthesized it. As the team noted, adding sodium produced a material with “extraordinary photoluminescence in the visible range.” The new material makes stable, single-emitter-based LEDs that converted nearly all the energy into white light.

The gigantic collection of calculations required to simulate new-material properties will dig even deeper with new HPC systems. Giustino is preparing to improve his work with Aurora, an exascale system the Argonne Leadership Computing Facility is installing. This computer, a thousand times faster than Theta, will combine standard processors with graphics processing units to accelerate calculations.

“We are making an effort to port our software to enable it for Aurora,” Giustino says. “For that, the experts at Argonne are extremely valuable because they will have deployed the machine, tested it and know the bottlenecks that we should look into to improve our codes.”

But a more advanced computer is not enough. “All these machines are awesome, but everybody needs to understand that it’s not just about buying a computer,” Giustino explains. “It’s about training the personnel and having enough funding to make it possible for software to evolve at the same pace.”

Not far ahead, Giustino envisions a more automated workflow. “I think we might be able to deliver integrated solutions that really don’t compromise on accuracy,” he says. “Then we can make a real impact on material science, and that’s the ultimate goal.”