Nuclear fusion offers the tantalizing possibility of clean, sustainable power – if tremendous scientific and engineering challenges are overcome. One key issue: Nuclear engineers must understand how extreme temperatures, particle speeds and magnetic field variations will affect the plasma – the superheated gas where fusion happens – and the reactor materials designed to contain it. Predicting these plasma-material interactions is critical for understanding the function and safety of these machines.

Brian Wirth of the University of Tennessee and the Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL) is working with colleagues on one piece of this complex challenge: simulating tungsten, the metal that armors a key reactor component in ITER, the France-based world’s largest tokamak fusion reactor. ITER is expected to begin first plasma experiments in 2025 with the hope of producing 10 times more power than is required to heat it. Wirth’s team is part of DOE’s Scientific Discovery through Advanced Computing (SciDAC) program, and has collaborated with the Advanced Tokamak Modeling (AToM), another SciDAC project to develop computer codes that model the full range of plasma physics and material reactions inside a tokamak.

“There’s no place today in a laboratory that can provide a similar environment to what we’re expecting on ITER,” Wirth says. “SciDAC and the high-performance computing (HPC) environment really give us an opportunity to simulate in advance how we expect the materials to perform, how we expect the plasma to perform, how we expect them to interact and talk to each other.” Modeling these features will help scientists learn about the effects of particular conditions and how long components might last. Such insights could support better design choices for fusion reactors.

A tokamak’s doughnut-shaped reaction chamber confines rapidly moving, extremely hot, gaseous hydrogen ions – deuterium and tritium – and electrons within a strong magnetic field as a plasma, the fourth state of matter. The ions collide and fuse, spitting out alpha particles (two neutrons and two protons bound together) and neutrons. The particles release their kinetic energy as heat, which can boil water to produce steam that spins electricity-generating turbines. Today’s tokamaks don’t employ temperatures and magnetic fields high enough to produce self-sustaining fusion, but ITER could approach those benchmarks, over the next decades, toward producing 500 MW from 50 MW of input heat.

Fusion plasmas must reach core temperatures up to hundreds of millions of degrees, and tokamak components could routinely experience temperatures approaching a thousand degrees – extreme conditions across a large range. Wirth’s group focuses on a component called the divertor, comprising 54 cassette assemblies that ring the doughnut’s base to funnel away waste gas and impurities. Each assembly includes a tungsten-armored plate supported by stainless steel. The divertor faces intensive plasma interactions. As the deuterium and tritium ions fuse, fast-moving neutrons, alpha particles and debris fall to the bottom of the reaction vessel and strike the divertor surface. Though only one part of the larger system, interactions between the metal and the reactive plasma have important implications for sustaining a fusion reaction and the durability of the divertor materials.

Wirth’s team can apply its own codes to characterize plasma particles as they interact with the tungsten and affect its surface.

Until recently, carbon fiber composites, protected divertors and other plasma-facing tokamak components, but such surfaces can react with tritium and retain it, a process that also limits recycling, the return of tritium to the plasma to continue the fusion reaction. Tungsten, with a melting point of more than 3,400 degrees, is expected to be more resilient. However, as plasma interacts with it, the ions can implant in the metal, forming bubbles or even diffusing hundreds of nanometers below the surface. Wirth and his colleagues are looking at how that process degrades the tungsten and quantifying the extent to which these interactions deplete tritium from the plasma. Both of these issues affect the rate of fusion reactions over time and can even entirely shut down, or quench, the fusion plasma.

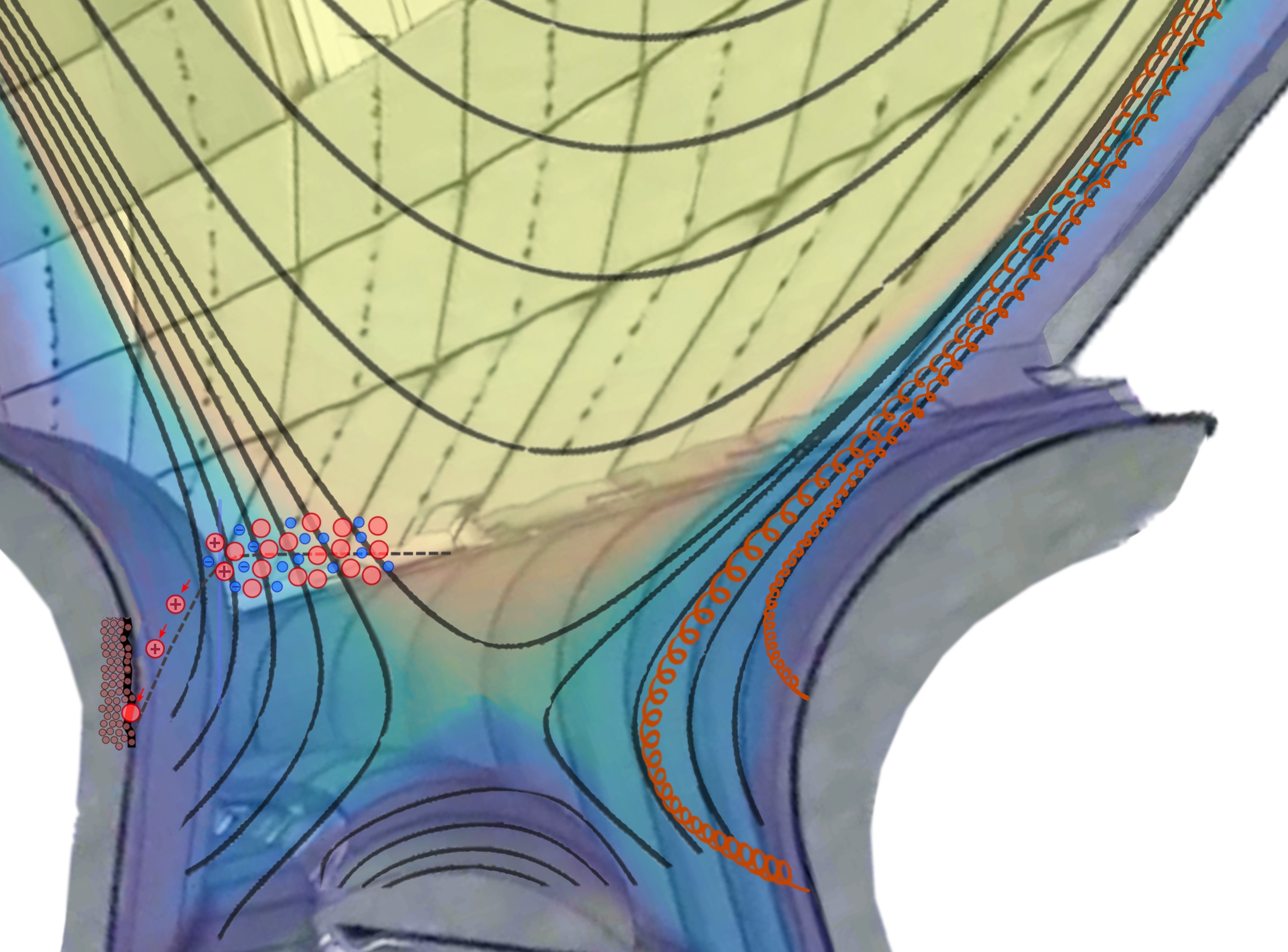

Exploring these questions requires integrating approaches at different time and length scales. The researchers use other SciDAC project codes to model the fundamental characteristics of the background plasma at steady state and how that energetic soup will interact with the divertor surface. Those results feed in to hPIC and F-TRIDYN, codes developed by Davide Curreli at the University of Illinois at Urbana-Champaign that describe the angles and energies of ions and alpha particles as they strike the tungsten surface. Building on those results, Wirth’s team can apply its own codes to characterize plasma particles as they interact with the tungsten and affect its surface.

Developing these codes required combining top-down and bottom-up design approaches. To understand tungsten and its interaction with the helium ions (alpha particles) the fusion reaction produces, Wirth’s team has used molecular dynamics (MD) techniques. The simulations examined 20 million atoms, a relatively modest number compared with the largest calculations that approach 100 times that size, he notes. But they follow the materials for longer times, approximately 1.5 microseconds, approximately 1,500 times longer than most MD simulations. Those longer spans provide physics benchmarks for the top-down approach they developed to simulate the interactions of tungsten and plasma particles within cluster dynamics in a code called Xolotl, after the Aztec god of lightning and death. As part of this work, University of Tennessee graduate student Tim Younkin also has developed GITR (pronounced “guitar” for Global Impurity Transport). “With GITR we simulate all the species that are eroded off the surface, where do they ionize, what are their orbits following the plasma physics and dynamics of the electromagnetism, where do they redeposit,” Wirth says.

The combination of codes has simulated several divertor operational scenarios on ITER, including a 100-second-long discharge of deuterium and tritium plasma designed to generate 100 MW of fusion power, about 20 percent of that which researchers plan to achieve on ITER. Overall the team found that the plasma causes tungsten to erode and re-deposit. Helium particles tend to erode tungsten, which could be a potential problem, Wirth says, though sometimes they also seem to block tritium from embedding deep within the tungsten, which could be beneficial overall because it would improve recycling.

Although these simulations are contributing important insights, they are just the first steps toward understanding realistic conditions within ITER. These initial models simulate plasma with steady heat and ion-particle fluxes, but conditions in an operating tokamak constantly change, Wirth notes, and could affect overall material performance. His group plans to incorporate those changes in future simulations.

The researchers also want to model beryllium, an element used to armor the main fusion chamber walls. Beryllium will also be eroded, transported and deposited into divertors, possibly altering the tungsten surface’s behavior.

The researchers must validate all of these results with experiments, some of which must await ITER’s operation. Wirth and his team also collaborate with the smaller WEST tokamak in France on experiments to validate their coupled SciDAC plasma-surface interaction codes.

Ultimately Wirth hopes these integrated codes will provide HPC tools that can truly predict physical response in these extreme systems. With that validation, he says, “we can think about using them to design better-functioning material components for even more aggressive operating conditions that could enable fusion to put energy on the grid.”