Since the 1960s, engineers have worked to quiet jet engines while boosting fuel efficiency and reducing air pollution. Over succeeding decades, they have refined designs to dampen the nozzle’s roar and muffle the fan’s buzz saw sound while enabling aircraft to fly farther on less fuel.

The Federal Aviation Administration projects an air-traffic increase of 0.8 percent annually to 2038. “We’re going to fly more,” says Peter Vincent of Imperial College London. “How can we do it whilst polluting less?”

Researchers have recently turned their attention to one particular source of noise and inefficiency: a device in the back of the engine called the low-pressure turbine (LPT). It harnesses some of the energy from the engine’s exhaust gases to drive a shaft that spins the fan and other mechanisms at the front of the engine. In the moments just after takeoff and just before landings, turbulent air flowing around LPTs can sometimes contribute a substantial fraction of the roar and drag in jet engines.

The air currents flowing through the LPT are complex, and improved designs that tame them will not come easy, Vincent says. To better understand the swirls and eddies of air surrounding the LPT, Vincent and his co-workers have developed PyFR, an open-source computer-simulation code that models air flow over, through and around solid structures, from aircraft turbines and landing gear to automobiles and trains.

PyFR has racked up impressive performance results. It was finalist in 2016 for the Association for Computing Machinery’s prestigious Gordon Bell Prize for outstanding achievement in high-performance computing.

PyFR is flexible and can operate efficiently on a range of parallel computing platforms, including CPUs, graphics processing units (GPUs) and Intel’s Many Integrated Core architecture. The code scales well even to the petascale levels – a million billion operations per second – available on Titan, a Cray XK7 supercomputer at the Oak Ridge Leadership Computing Facility, a DOE Office of Science user facility.

‘The geometries are complicated and the flow is very unsteady.’

Vincent and his colleagues have been using an award of 180 million processor hours on Titan from the Department of Energy Innovative and Novel Computational Impact on Theory and Experiment (INCITE) program to study flows around an LPT developed by MTU Aero Engines, a German manufacturer. The work includes the company’s Ralf-Dietmar Baier and Antony Jameson of Stanford University, “the father of modern CFD,” Vincent says.

“The challenge for all of these flow problems is that the geometries are complicated and the flow is very unsteady, so it’s not just turbulent,” Vincent says. PyFR is designed to solve for those complications. Faster and more accurate than other computational fluid dynamics (CFD) methods, PyFR simulations show promise for developing new turbine designs, reducing the cost and time involved in experiments.

PyFR relies on a flux reconstruction approach (the FR in its name). This method employs a more flexible and accurate strategy for understanding the complexities of flowing fluids, represented by curves. Traditional CFD codes slice the area under the curve into small, finite volumes, then solve for each, yielding an approximation of the underlying function that connects them. High-order flux reconstruction breaks the curve into short segments, then finds a Lagrange polynomial, an equation describing a new curve that passes through all key points on each segment, thus closely matching the segment. Using the Lagrange polynomials, the code then solves for the area under the curve in chunks instead of small volumes, yielding more accurate results with less computation time.

Researchers can adapt this code to a range of shapes and configurations because it’s built on unstructured grids. Unlike Cartesian grids – networks of tessellated cubes stacked neatly at right angles to each other – unstructured grids combine pyramids, tetrahedra, prisms, cylinders and other shapes to represent complex three-dimensional geometries, such as the tires, rims, struts and panels in landing gear.

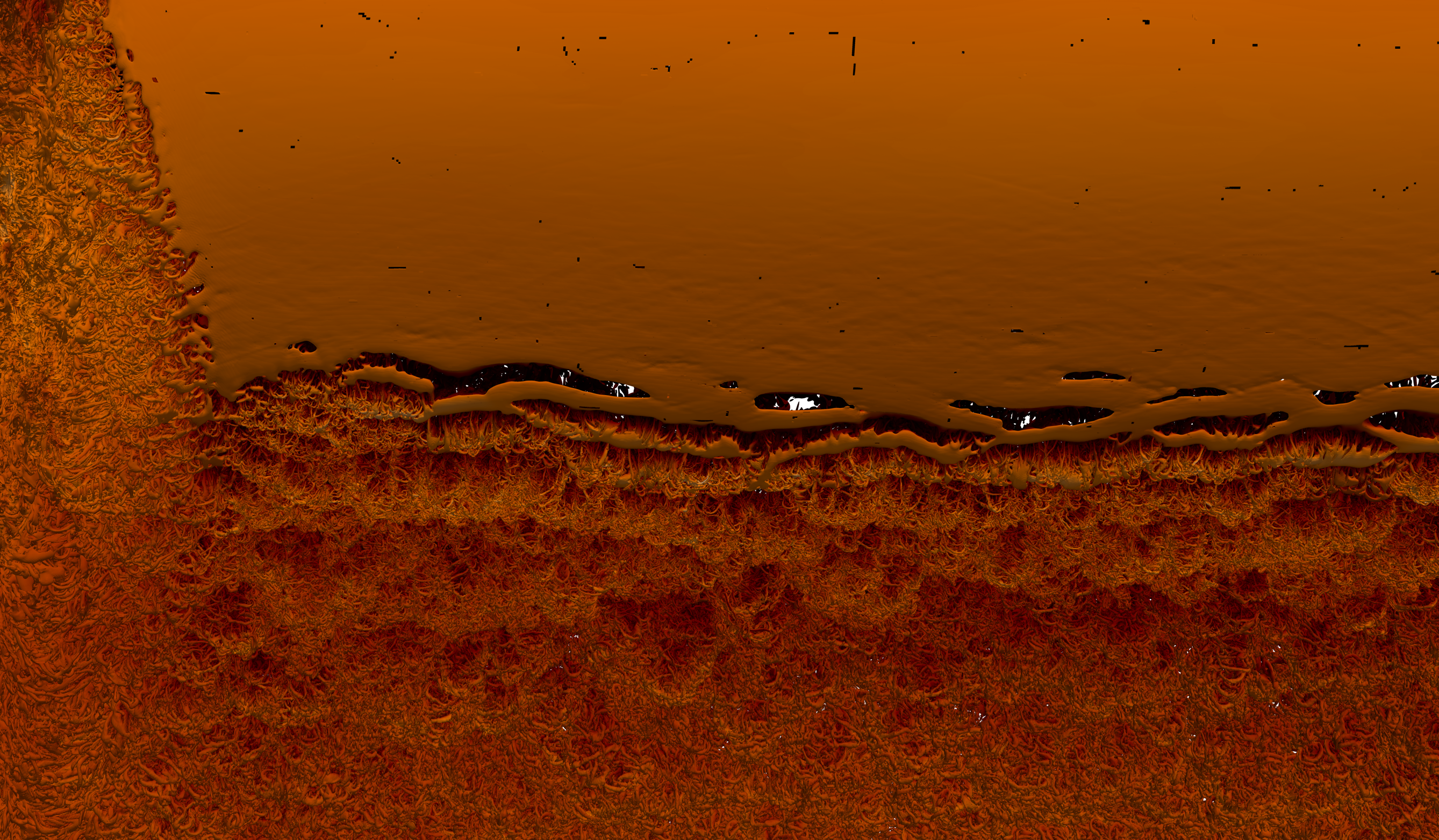

The team’s INCITE project has simulated air flow over one of MTU’s LPT models at unprecedented scale and resolution, modeling three flow passes over each of five blades, simulating both wave phenomena and turbulence, plus the wake behind the blades.

These simulations can produce petabytes of data – enough to fill thousands of desktop hard drives – which makes storing and processing them offline challenging. “You have to extract information as you go along,” Vincent says. So, the team has been developing in situ visualization, a feature that produces animations of simulation results as they’re generated. PyFR processes and renders the data and spits out a PNG image, he says.

Taking this visualization technology further, the researchers are adding a feature that allows scientists to zoom in on small flow volumes live. The PyFR team also is exploring a machine-learning component that could automatically single out results of interest.