When Doug Kothe entered nuclear engineering school in 1983, the graduate chairman had this message: Don’t worry about a job. There are lots of nuclear reactors to decommission.

That was then.

Three decades later, Kothe is leading one of the most significant U.S. nuclear engineering research and development projects in a generation. But the amazing reactor he’s helping build doesn’t use steel and concrete. It’s virtual.

Kothe directs the new Consortium for Advanced Simulation of Light Water Reactors (CASL). The five-year, $122 million project is the Department of Energy’s (DOE’s) first energy innovation hub and is supported by its Office of Nuclear Energy.

CASL brings together about two dozen national labs, universities and industry partners to create a virtual reactor that – using the world’s three most powerful computers – will point the way toward a new era of U.S. reactor design.

“CASL comes at an opportune time for the U.S. nuclear industry,” says Kothe, who is based at Oak Ridge National Laboratory (ORNL) where he previously was director of science in the Oak Ridge Leadership Computing Facility.

“There’s a nuclear power renaissance under way, and it requires a similar transformation when it comes to the industry’s use of high-performance computing.”

‘I’ve worked with industry, in a university and with the DOE labs, but I’ve never worked with all three of them together. CASL is a new paradigm for the nuclear industry.’

After three decades of economic doldrums for the U.S. nuclear industry – sparked by plant cost overruns, the 1979 Three Mile Island accident and a drop in oil prices following the energy crises of the middle and late 1970s – nuclear power is once again an attractive energy source: reliable, domestic, and now importantly, carbon-free. In February, the Obama administration approved an $8 billion loan guarantee for construction of two reactors in Georgia. If the project goes forward, they’ll be the first plants to start construction in the United States since the 1970s.

However, with low R&D investment in the past decades, the advanced high-performance computing (HPC) muscle that previously drove innovation in the nuclear industry has withered to a shadow of its former self.

“At that time the nuclear industry was the leader in industry using HPC,” says Paul Turinsky, CASL lead scientist and North Carolina State University nuclear engineering professor and department head.

Turinsky worked as a nuclear engineer for Westinghouse from 1973 to 1980. “We were the guys who bought $20 million CDC 7600 computers. People didn’t talk about Boeing or pharmaceutical companies or Ford Motor with all its crash-simulation software. None of that existed then.”

Today, however, Turinsky and his graduate students run their simulations not on HPCs, but on desktop computers.

He says this lack of HPC modeling and simulation ability is a brake on innovation. For example, although there have been advances in the more efficient use of nuclear fuels, fuel assembly designs and materials have remained essentially unchanged since the ’70s.

The main reason for this innovation roadblock? Utilities, vendors and the Nuclear Regulatory Commission (NRC) don’t want to run the safety, liability or cost risks associated with using unproven technologies.

“Today,” Turinsky says, “if you want to do something pretty different with materials or assemblies, the question is could you do it? And I think the answer, without HPC prediction capability, is no.”

Existing nuclear reactor computer models are calibrated. they’re based on observed data rather than predictive models based on scientific first principles.

“We need to increase confidence in these existing calibrated modeling tools outside the experimental space they’re validated against,” Kothe says. “CASL’s challenge is taking these legacy tools that are used to make day-to-day decisions and that have done amazing things in getting 104 U.S. reactors operating safely and efficiently, and pushing them to the next level.”

When it comes to how this will be accomplished, Kothe combines a show-me-the-goods pragmatism with a visionary’s zeal. He’s keenly aware of the daily challenges commercial operators face.

“The focus of CASL is all about here and now,” Kothe says. “We really need to get good experience first in validating our codes and developing confidence in predicting the here and now before we go off and claim to help design the advanced reactors of the future. We need to show both DOE and the owner-operators that we can simulate what already exists.”

For the nuclear industry the here and now is all about nuclear plant lifetime extensions and power uprates, which involve increasing the maximum power level at which a plant may operate.

Most U.S. nuclear plants were designed to last 40 years, the maximum term under the NRC’s licensing regime. The plants have proven much more resilient than anyone imagined. In 2009 the NRC granted a 20-year license extension to Oyster Creek (located 50 miles east of Philadelphia), which came online in 1969 and is the oldest operating nuclear plant in the United States. The average U.S. nuclear plant is 30 years old and more than half have already received 20-year extensions, with another 28 awaiting approval.

Now the big question is whether these aging plants can operate safely and efficiently for up to 80 years. The answer has enormous economic implications because it’s much cheaper to renovate a facility than build a new one.

“This is where advanced modeling and simulation can play a major role,” Kothe says. “What CASL will provide is much like what HPC has given the aging nuclear stockpile through the Advanced Simulation and Computing Program in DOE’s National Nuclear Security Agency: the ability to guide decisions with insight gained from predictive modeling.”

Power uprates are an NRC licensing condition. Since 1977 utilities have been able to squeeze more than 5 gigawatts of additional power from existing reactors by altering fuel regimes and reducing uncertainties in predictions. However, the margin for improvement is now smaller, and any further advances will likely need predictive modeling, Kothe says.

Chief Scientist Turinsky says that to meet these needs, CASL will primarily focus on developing improved models of reactor materials and fluid dynamics – two critical components of both reactor aging and efficiency.

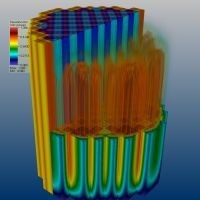

The CASL team will begin by modeling the contents of the reactor vessels of pressurized water reactors, the most common type of light water reactor in the United States. The reactor vessel contains a plant’s nuclear heart, hundreds of 12-foot-long pencil-thin fuel rods, each filled with several hundred fuel pellets, and the rods grouped into assemblies.

Until now, fuel content and assembly has been modified based on a “cook and look” model – burn the fuel and then examine it. It’s a process that can take 15 years from idea to implementation.

“What we want to do is develop a tool and a code to understand how one pellet,” Kothe says, “and then one fuel rod, all the way up to a full assembly, functions in a reactor and to do this as much as possible based on fundamental equations and first principles so that it’s widely predictive.”

The fluid dynamics in a reactor are similar to heating a pot of water on an electric stove. If the coil is the equivalent of the nuclear fuel, the inside of the pot is the outside of the fuel cladding, which is where water vapor bubbles form, temporarily adhere, then rise into the surrounding cooler water.

“People haven’t been totally successfully in modeling the fluid dynamics,” Turinsky says. “If you look at the physics, it’s very, very complicated.”

Yet it’s a primary issue for reactor performance. If the fuel rods have too high a power output, a steam layer can develop, which dramatically lowers the heat transfer, resulting in melting of the fuel-rod cladding.

“If we can understand what’s going on with the bubbles, we’ll get a better understanding of the safety concern called critical heat flux, which also impacts fuel cycle costs,” Turinsky explains.

Kothe notes that CASL will draw on the broad base of experience already developed by other HPC user communities, including the fusion research community.

“Without DOE’s Office of Advanced Scientific Computing Research (ASCR) we wouldn’t have a pyramid to build on,” he says.

CASL’s intricately detailed advanced simulations will only be possible because of the powerful computers on which they’ll run: Jaguar, located at ORNL and the nation’s most powerful computer; Kraken, also at ORNL; and Roadrunner at Los Alamos National Laboratory.

Present desktop reactor core simulations use a broad array of data averaging and estimates to run models. The CASL models and simulations are targeted to be fully scalable, replacing many approximations with more fundamental equations and first-principle approaches. This will enable CASL to produce predictive models with clear uncertainty quantifications, a key licensing issue for the NRC.

Whereas the first pieces of CASL computer models and applications are just beginning to come together, the program already is transforming the U.S. nuclear industry and setting the stage for new insights.

“This is really exciting,” Turinsky says. “I’ve worked with industry, in a university and with the DOE labs, but I’ve never worked with all three of them together. CASL is a new paradigm for the nuclear industry.”

And one that’s working. Dr. Turinsky notes that at the first CASL meetings, team members sat with their workplace affiliates. Now, he says, team members cluster based on their technical interests, creating the dynamics for new ideas.

Three decades after enrolling in a program to become a nuclear engineer, Kothe is finally getting a chance to dream not about how to shut down nuclear reactors but how to improve existing ones and design the advanced reactors of the future.

Says Kothe, “We’re confident that the kinds of simulation tools we’re going to develop will be able to support exciting advanced reactor designs.”