A biomass bonanza surrounds the Ames Laboratory offices of Mark Gordon, Monica Lamm and Theresa Windus – if only they can find an efficient way to get at it.

Iowa farmers plant millions of acres of corn and soybeans. Over the years, more and more of the crops they raise have been converted into renewable ethanol and biodiesel fuels.

There’s even more power in the biomass – leaves, stalks and stems – left behind in the field. Lignocellulose, the woody stuff that makes plants rigid, could be a plentiful source of carbon-neutral, renewable energy. Wood chips, grasses, wheat chaff – just about any plant material is a potential alcohol fuel feedstock.

Only if it adds up, Gordon says. “If you’re going to use biomass to produce energy, how much energy does it take to do that?” It’s a big issue – one Gordon, Lamm and Windus hope to help decipher with supercomputers and clever mathematics.

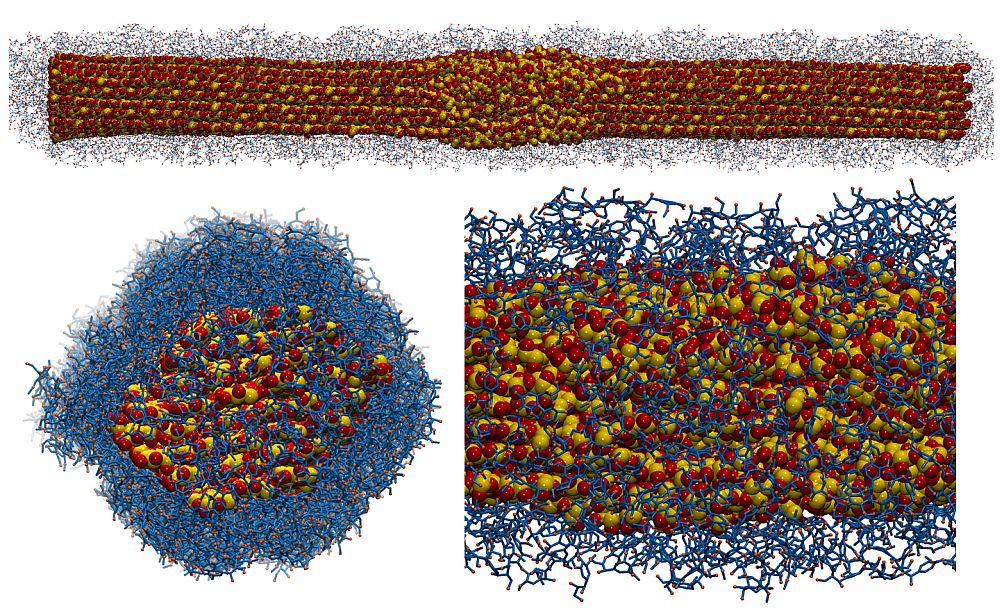

The problem: Lignocellulose doesn’t give up easily. First, the fermentable sugars are contained in compact, partially crystalline cellulose fibrils that resist hydrolysis – the enzymatic process that breaks them apart. Second, polysaccharides – chains of sugars – and woody lignin cover the fibrils, creating another barrier to enzymes.

Busting those obstacles isn’t cheap, in energy or in dollars. It takes lots of heat or chemicals, making lignocellulosic biomass an impractical ethanol feedstock.

At least for now. The Department of Energy is seeking economical ways to convert biomass. The researchers at Ames Laboratory, a DOE facility, are collaborating on one such project, together with a group led by Jeremy Smith, director of the Center for Molecular Biophysics (CMB) at Oak Ridge National Laboratory and the University of Tennessee, and Xiaolin Cheng, an ORNL staff scientist at the center.

The groups are out to create mathematical methods and high-performance computational approaches that can model bigger lignocellulose molecules for a longer time, Cheng says, and with greater computer efficiency and accuracy. The work is supported by DOE’s Scientific Discovery through Advanced Computing (SciDAC) program through DOE’s offices of Advanced Scientific Computing Research and Biological and Environmental Research.

‘Quantum mechanics is accurate but very expensive.’

Both groups are developing molecular dynamics (MD) lignocellulose simulations. MD calculates the physical movements of atoms and molecules through time. The CMB’s MD model uses molecular mechanics to calculate potential energies of the lignocellulose system. Molecular mechanics is based on classical physics, the predictable rules that govern the universe’s large-scale behavior. For example, classical physics includes Newton’s laws of motion and gravity.

The Ames Lab group’s starting point is quantum mechanics (QM), the strange laws in play at the tiny scale of molecules, atoms and subatomic particles. In the quantum realm, energy and matter act and interact as both particles and waves. Particles absorb energy only in discrete amounts, or quanta, and one particle can influence another’s behavior even over a great distance.

“These molecular dynamic simulations we’re talking about could use any intermolecular potential,” Windus says, as long as they aren’t too “computationally expensive” – they don’t demand excessive computer power. “Traditional molecular mechanics potentials are inexpensive but they might also be inaccurate. Quantum mechanics is accurate but very expensive.”

There’s another key difference: Molecular mechanics can’t calculate the energy needed to break most chemical bonds – only weak hydrogen bonds. “If you want to calculate the hydrogen bond energy with very high accuracy, even the molecular mechanics methods will not be sufficient,” Cheng says.

The crux of the problem is “we need very high-accuracy quantum mechanics to understand the critical local interactions. But if we want to understand the systems-level phenomena, we really need cheaper methods.”

Gordon and Windus, who also are Iowa State University chemistry professors, specialize in QM and developed GAMESS (General Atomic and Molecular Electronic Structure System), a quantum mechanics-based code for molecular chemistry. Lamm, who also is an ISU chemical and biological engineering associate professor, focuses on molecular dynamics simulations and how small-scale factors affect large molecules.

With a cadre of graduate students and post-doctoral researchers, they’re developing techniques to convert expensive quantum mechanics models into manageable molecular mechanics-type models.

“You have these cellulose strands that are chains of glucose,” Windus says. “We can learn a lot through molecular dynamics about how these strands start to separate, but if we want to know how to take that and get it to ethanol production, we have to break more than just the hydrogen bonds in those chains. We actually have to start breaking the chains themselves.”

“We have to understand how much energy that takes,” Gordon adds.

“And,” Lamm says, “we need the quantum-scale calculations for that, because molecular mechanics doesn’t break bonds.”

Here’s how it works: The researchers do a molecular dynamics simulation with quantum mechanics for as long as possible given the computer power. With luck, it’s enough to transform the QM potential into a coarse-grained, more tractable molecular mechanics potential. “You can do simulations for much longer times,” Gordon says. “Each step costs much less with the coarse-grained potentials. We’re talking orders of magnitude less” but, he hopes, with comparable accuracy.

GAMESS is the Ames researchers’ main vehicle, supplying tools to do QM calculations and bridge them to the coarse-grained molecular mechanics model. The first tool, the Fragment Molecular Orbital method (FMO), can perform highly accurate QM calculations for a large system, such as lignocellulose.

FMO divides a large molecule into fragments. Quantum mechanical potentials for each fragment are calculated on a different processor node in a massively parallel computer – one made up of thousands of individual processors. That makes FMO run well on parallel machines.

“The big gain is that if two pieces of the molecule are far enough apart from each other, we say ‘OK we don’t really need quantum mechanics anymore for that,’” Gordon says. Instead, the researchers apply a less demanding molecular mechanics method to those parts. “That’s what makes it as fast as it is.”

FMO lets the Ames researchers do QM calculations on larger systems. “It’s really the way we’d like to do everything, if we could afford it,” Gordon says. Even on big computers, it is expensive for molecular dynamics problems.

FMO is necessary for simulations that include breaking chemical bonds. In other cases, or for larger molecules, the researchers turn to another tool in GAMESS: The General Effective Fragment Potential, or EFP.

“You can think of FMO and EFP as two different starting points, depending on what you think you can afford,” Gordon says. But “in real life, all the processes involving lignocellulose have solvents involved,” and EFP is designed to simulate solvents. GAMESS makes the two work together, so it’s possible to simulate lignocellulose with FMO and solvents with EFP.

EFP breaks the fundamental ways molecules and ions interact into five energy potentials, and it calculates each separately. Other models fit potentials to experimental data; EFP instead starts from first principles – the fundamental physics – with no assumptions or fitting. “That’s really the key,” Gordon adds.

Like standard molecular mechanics approaches, EFP calculates model potentials, but EFP’s model potentials are derived from quantum mechanics. That makes it more accurate than conventional molecular mechanics, but computationally cheaper than QM. “It’s in the middle, but more toward molecular mechanics,” Gordon says. “EFP really helps us bridge the quantum mechanics to molecular mechanics gap and the time scale gap to some degree.”

There’s a last step to running longer, larger lignocellulose simulations: coarse graining. Coarse graining takes the atomic-level interactions calculated with QM or model potential methods (like EFP) and lets researchers observe what happens at the level of a whole molecule, Cheng says.

In essence, the Ames researchers use EFP, FMO or a combination (though for now they mostly rely on EFP) to calculate potentials for as long as computationally affordable. Then they put atoms into groups and calculate their potentials using LAMMPS, a classical molecular dynamics code.

“These coarse-graining methods are taking the more accurate MD simulations and building better molecular mechanics potentials,” Windus says. “Instead of thinking of every atom as an atom, you’re thinking about chunks of a molecule.” With fewer particles to track, the molecular mechanics MD simulation is more computationally tractable.

“Of course, when you make the coarse-grained potential you worry about the accuracy,” Gordon says. Lamm, postdoctoral researchers Yana Kholod and Sergiy Markutsya and former graduate student Gaurav Pranami have focused on the coarse-graining process and on examining results to ensure their accuracy is acceptable relative to quantum mechanics.

Lyudmila Slipchenko, a former Gordon postdoc and now an assistant professor at Purdue University, also played a key role in developing the coarse-graining method. Meanwhile, John Baluyut, another graduate student, is performing accurate calculations of the energy needed to break glucose chains.

The ORNL group, besides calculating molecular mechanical potentials in a different way, also does coarse graining differently. One of the researchers’ goals is to compare how well the two approaches predict lignocellulose properties.

It will be the first time the two methods have been compared head to head, Lamm says, but first the groups must agree on the problem. “It may seem simple, but you really have to define the system you’re doing the comparison on very well to rule out any kind of confounding factors.” The groups are working that out now, and each hopes to send some of its researchers to the other lab soon.